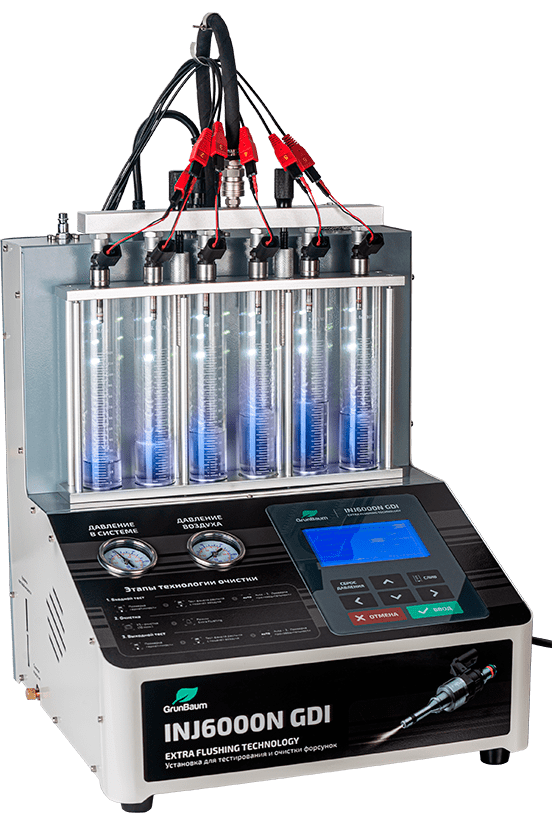

Special testing modes for GDI and FSI

Detect over 90% of injector failures

Why is 9 bar pressure

is enough to test GDI and FSI injectors?

- Fluid pressure is the same above and below the atomizer armature

- The spray pattern is the same in all operating modes of the internal combustion engine

- The permissible pressure pulsations in the ramp on the test bench are achieved at a pressure of 9 bar

- 9 bar pressure guarantees safe work

IT'S TIME TO GET INTO GDI

Get professional advice

from a technical specialist

EXTRA FLUSHING

Technology

Technology that cleans more than 60% of dirt types

Cleans all types of dirt

Removal of hard carbon deposits

Removal of tar deposits

Corrosion cleaning

Functional capabilities

Cleaning intensity adjustment

Evaluation of cleaning results

Additional cleaning with compressed air

EXTRA FLUSHING IN WORK

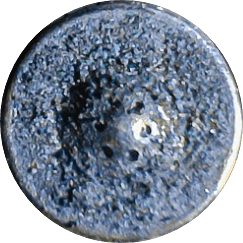

Jaguar XF, 2010, 120,000 km with rough idle

Before flushing

-

External signs:

irregular idling -

Diagnostics on the vehicle:

no error codes -

ECU fuel mixture adjustment (54.69%):

not available

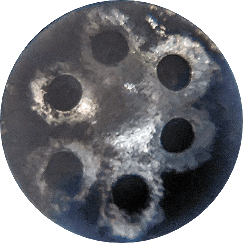

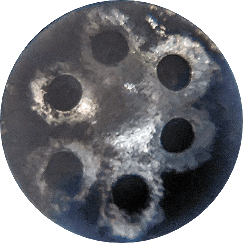

After flushing

-

External signs:

irregularity idle speed has been eliminated -

Diagnostics on the vehicle:

no error codes -

ECU fuel mixture correction (15.62%):

available

EXTRA FLUSHING

Includes the advantages of classic flushes

and eliminates their disadvantages

EXTRA FLUSHING |

On-vehicle cleaning |

Cleaning in an ultrasonic bath |

|

| Chemical cleaning | Yes | Yes | No |

| Ultrasonic cleaning | Yes | No | Yes |

| Check before cleaning | Yes | No | Yes |

| Check after cleaning | Yes | No | Yes |

| Visibility for the client | Yes | By indirect parameters | Yes |

Reliability and safety

GRUNBAUM — winner of the award

«Golden Key. Choice of service stations»

GRUNBAUM — winner of the award

«Golden Key. Choice of service stations»

IT'S TIME TO GET INTO GDI

Get professional advice

from a technical specialist

WE'LL HELP YOU TO GET THINGS STRAIGHT

10

VIDEOS ON THE GDI

AND FSI ARRANGEMENT

5

VIDEO TUTORIALS

FOR THE BENCH

1

DAY OF PRACTICE

IN THE LAB